Resurrecting an Airhead from the ashes of misfortune

Coming home from dinner one night, I on my airhead and Gill on her Ninja, I noticed a puff of white

from behind the fairing as I approached a red light. As we pulled to a stop, I heard her yelling "You're on fire!"

That was instantly apparent from the smoke that came billowing out

when we came to a standstill. I got the bike to the side of the road,

hit the kill switch, turned the key off and stepped away. I could see an

orange glow inside the headlight bucket but there were no open flames,

so I popped the seat off and removed the gas tank. Fortunately, the tank

is only held on by two thumbscrews, so the whole enterprise took maybe 20

seconds. I noticed the headlight was still on, so I grabbed a wrench,

disconnected the battery and waited.

Eventually the smoke died down and there was no further sign of fire.

When we got the bike back to the garage, I could see burnt wiring under

the fairing. That weekend, the teardown started and the prognosis was

not good.

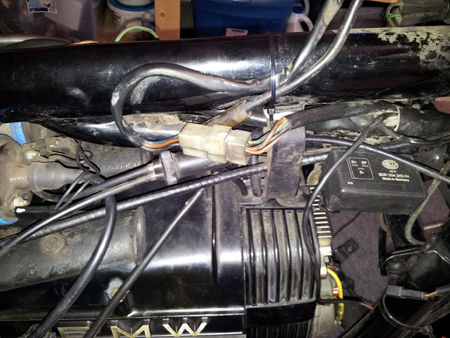

With the fairing off, you could see that all of the wiring that went

to the voltmeter and clock had overheated. With the handlebars,

instruments and switchgear removed, it looked even worse. What hadn't

cooked outright was still damaged by contact with hot wiring.

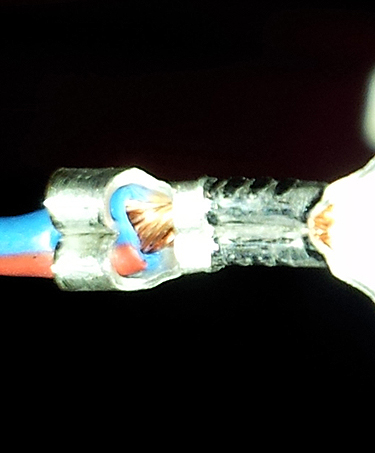

And the damage went all the way back through the harness. Some of it

looked fine, but beneath the plastic sheathing, there was carnage. Here's a

section from the headlight bucket down to a connector that joins to the

turn signals. It got so hot that the connector melted together and had

to be pried apart.

None of this was typical. Most airheads do not barbecue their wiring

on a whim. While I was not able to determine the exact cause of the

conflagration, I have two theories. One is that there was a short

somewhere in the old wiring. I certainly found a fair share of poorly

done bodges in the old harness. A more plausible explanation came from

Rick at Motorrad Elektrik, who

is the go-to guy for anything having to do with boxer wiring. He said

such extensive damage was rare, but he had seen some that overheated

when the headlight relay shorted.

Turns out that on an airhead, the headlight is not fused. If the

relay shorts, the wiring harness gets full voltage and heats up quickly.

This makes the most sense. When it happened, I hit the kill switch and

turned the ignition key off, but the headlight remained on until I

disconnected the battery - indicating a direct short.

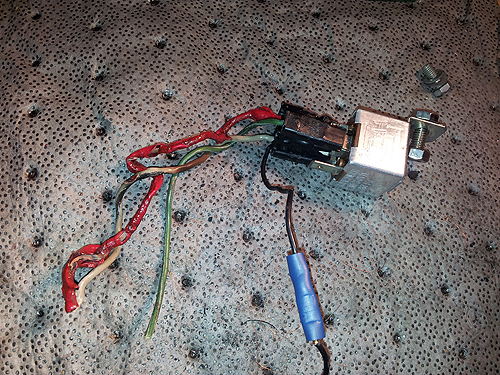

Then there's the relay itself.

Yes, that's fried. And no, I did not put that barrel crimp connector

on.

Regardless of the cause, the extensive damage meant the whole wiring harness would have to be

replaced - a daunting and expensive proposition. New, complete wiring

harnesses are listed for around $700. They are also listed as "no longer

available." Really handy people with lots of time on their hands can

create their own harness, either duplicating the original or going full

custom. I went the third route and hit E-bay, finally settling on a used

harness, complete with headlight bucket and every bit of wiring,

including the connector for the instrument pod, from a one-year-older

model R100RT in good shape for a little over $100. Because the seller had not

ripped the wiring out of the bucket, that meant I'd save some time and

effort, since I wouldn't have to thread as much wiring into the bucket.

It was important to get the right harness - wiring changed somewhat

every few years, and the RT/RS harness includes wiring for the clock and

voltmeter. I purchased the closest thing I could get to the original

harness for my year and model.

Replacing the whole harness was actually for the best, as it gave me

the opportunity to correct a lot of issues.

The Saint's bike |

You see, my old airhead had a hard life. It came into this world as an R100RS

with a big touring fairing, like the one Roger Moore rode in the TV show

"The Saint. It went through several owners, including one who tried to

convert it to a "CS" model, which was BMW's '80s update of the venerable

R90S, with the classic bullet-style bikini fairing.

That meant a bunch

of wiring and hardware changes, since the RS has a full dashboard where the key resides, and

front turn signals up in the fixed fairing instead of on stalks. Eventually it wound up

in the hands of a well-meaning BMW car enthusiast (yes, BMW makes cars

too!) who "restored" it. I've been dealing with the fallout from those

previous owners ever since.

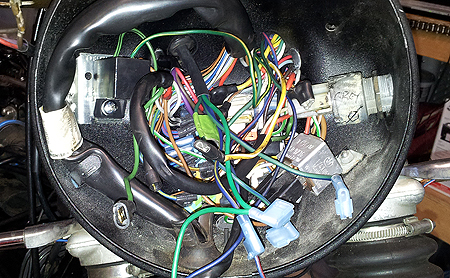

For instance, living inside the headlight bucket there were some

seriously WTF things

like this...

and this...

Wire nuts? Really? And I don't care how much military-grade rubber

tape you wrap things up in - you are doing it wrong. Very, very wrong.

That ignition barrel? Careful, archaeological-quality unlayering

revealed this:

It's a wonder the bike ever started with that. It's a wonder nothing

caught on fire sooner.

Before total disassembly, I made sure to mark everything.

In fact, before taking off the old harness, I took pictures of the

routing, because the replacement harness should follow the routing

exactly - there's not much room for error, and you want everything to

reach without rubbing or being pinched. I probably took 40 photos for reference - how wires were routed, how

and where they were secured, where the connectors were. It doesn't

matter how good the pictures are - as long as you can tell what is going

where, because you will NOT remember where it all goes. I also used tape

to tag parts of the old harness and indicate what went where for

comparison when I put on the new one.

Since I had bought the harness with the bucket, I just had to set the

bucket in place and run the main trunks back onto the frame and connect

everything up, using the photos as reference. That part was fairly

straightforward.

The real fun was up inside the headlight bucket, which is the heart

and soul of the system. On old airheads, everything connects up to a

festively-coloured board in the back. That's an empty bucket and board on the right.

In theory, wiring everything up is ridiculously simple. The board has

spade tabs set into coloured areas.

The

colours correspond with the colours of the wires in the harness. All you

have to do is match the colour of the wire to the colour on the board.

So if you have a green wire, it plugs onto one of the tabs in the green

area. A red wire plugs into the red area. If you have a green wire with

a black stripe, it goes on a tab in the green/black area and so forth. It's an

incredibly clever system - simple, logical, German. The

colours correspond with the colours of the wires in the harness. All you

have to do is match the colour of the wire to the colour on the board.

So if you have a green wire, it plugs onto one of the tabs in the green

area. A red wire plugs into the red area. If you have a green wire with

a black stripe, it goes on a tab in the green/black area and so forth. It's an

incredibly clever system - simple, logical, German.

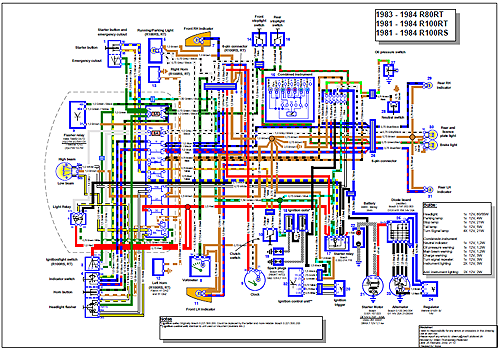

Unfortunately, we are not dealing with a brand-new entirely stock

motorbike with factory-correct and matching model-year parts. In

the course of 30 years it had been hacked, bodged, repaired and rigged.

The same goes for the used part that was being retrofit.

Wires of a certain colour on the new (used) harness did not always

match wires from the old harness, when I could tell what colour the

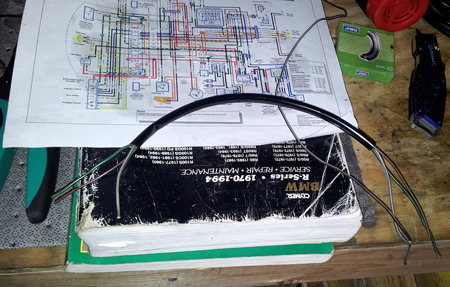

wires were before they were cooked. Also, I employed three different

diagrams. The ones in my two old manuals are black-and-white, with wire

colours indicated with letters, but the letters were not intuitive. For

instance, black wires were indicated with "sw," which is short for the

German word for black, "schwartz," and other abbreviations were for the

German too. Additionally, none of the wiring diagrams entirely agreed

with one another, or with what was on the harness. The most useful diagram was this one, in colour.

However, it is for a European spec RS/RT, so the turn signals are in

a different place and it includes an on/off switch for the headlight on

the left switch assembly.

It can all be overwhelming. The best advice is to take things slowly,

one wire at a time, and stop when you get frustrated. Things will be

much clearer when you come back to it another day. Beer helps.

The biggest issues I ran into involved the switchgear, which was not

included with the replacement harness, and turn signals; the harness

was from an RT, with signals in the fairing.

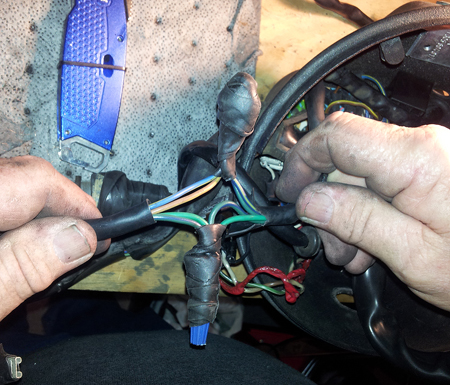

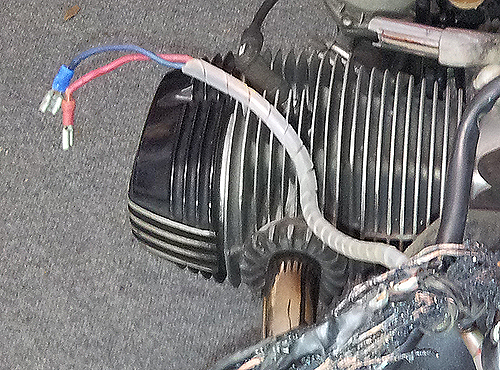

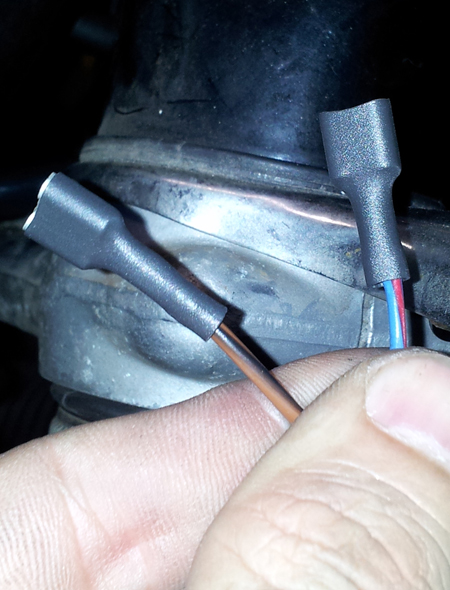

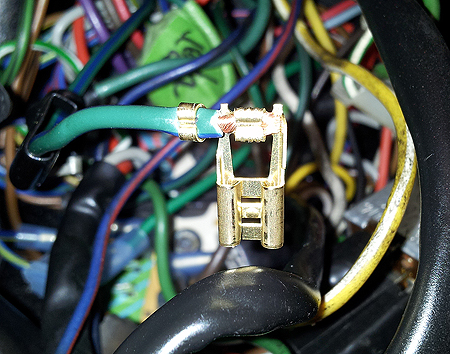

Signals first... Here's a close-up of wiring that was on the bike:

On an original BMW, the hot wire to the right turn signal is blue

with a black stripe and the ground wire is brown. The left signal is

blue with a red stripe and another brown. This is none of those. It also

has exposed female spade connectors from Lowe's and cheezy plastic wire

protector stuff from an auto parts store. That's fine if you're in a

bind and need a temporary fix. But it is not right.

My initial inclination was to do a functional-if-incorrect fix of my

own, but after some deliberation (and beer) I decided that since I did

not need the bike to function immediately, I would do it properly, even

if it meant taking a longer time - the "waitin' on parts, man!" portion

of any project.

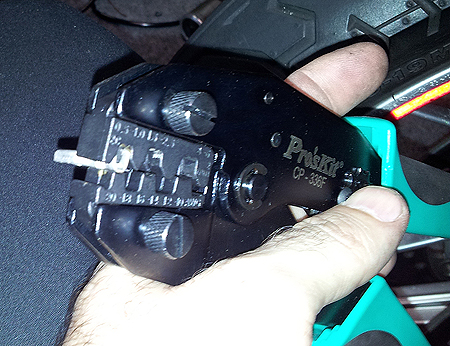

I salvaged the proper colored wires from an uncooked section of the

old harness. I also ordered factory-style, crimp-on connectors and a

crimping tool from

Cycleterminal.com. Service was fast and I'll deal with them again. Good folks.

Here's the tool and a connector.

Basically, you just strip off a small bit of insulation from the wire

(no more than 3/8") and twist the strands. Put the connector in the die,

slide the wire in and squeeze.

The die has two sections - one crimps around the wire at the insulation

to provide strain relief and

the other tightens the bare wire securely to the connector, at the same time.

It takes a little practice, and the tool costs more, but the results

are far better than anything you'll get with the typical hardware-store

connectors and crimpers. Once the connectors are on, cut some heat

shrink tubing and hit it with the heat gun.

OCD readers will note that in the picture above, I used a brown/black

wire rather than plain brown for my ground. Unfortunately, I couldn't

salvage enough plain brown wire. Some future mechanic will probably

curse my impropriety.

On a proper R100/7, the wires for the signals run from the headlight

bucket through small holes in the fork covers and out to the stalks.

This would require removing the forks and while I want to do things

right, that's hours of additional work. Instead, I ran them behind the forks, to the

stalks, wrapped in factory-style black sheathing. Everything is

therefore weatherproof and since the stalks move as a unit with the

forks and headlight, there is no chafing. When I service the forks, I'll

route the wires properly.

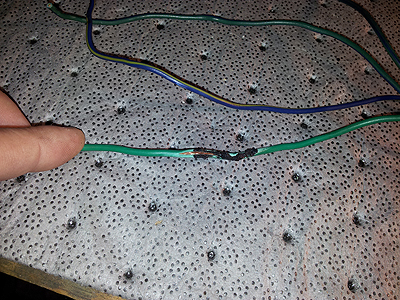

The switchgear was in reasonably good shape, but the wiring had been

damaged by contact with hot wires. Mostly it was just melted insulation.

I cut away the protective sheathing to assess the damage.

Fortunately, most of it was at the far end, away from the switch. Since

the bike had been converted from "RS" to "S," it had shorter handlebars.

But the previous owner hadn't bought "S"-style switchgear, so the wires

were longer. That was a lucky break! It was then just a matter of cutting off the irreparable

wiring at the far end and repairing the remaining damaged insulation with some heavy-duty heat

shrink.

And then sliding the wires into a new sheath.

You'll note that there are no terminals on the end of the wires up

there. That made the wires easier to thread into the headlight bucket.

Once inside, though, things got tricky.

Because the designers put a headlight in the headlight bucket, in

addition to wiring, they needed plenty of room. You can't use a normal

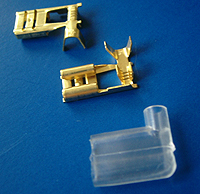

connector like this:

Plugged straight into the board would mean you lose almost an inch of

depth to make room for all of the wires, robbing valuable space. Instead, the

factory uses a right-angle

gizmo called a "flag terminal," I guess on accounta it looks like a flag

when the wire's attached. This puts the wires out to the side.

The ones available at your local auto parts store look like this:

That's what I bought, initially. And I started installing them.

However, in addition to not being factory-correct, I quickly

found another problem. They were too large! The tabs on the board are

fairly close together and everything's a tight fit. I was not going to

get all of the connectors on.

The proper solution

would be to get factory-style flag terminals, again from Cycleterminal.

I also ordered black insulators rather than the clear that you see in

the picture.

However, because of their design, the regular die on the crimping

tool does not work on the flags. To make a long story short, I ended up

using a German crimping tool from

Goodspeed Motoring.

Sure, it looks like the generic stripper-crimper you can get at Harbor

Freight.

But get closer. The jaws of are made to hold the connector at the base

and fold the tangs over.

And that makes all the difference. With a little practice, the results

are factory-grade.

Note that you have to put the insulator on BEFORE attaching the

terminal. Duh.

Here's the difference between the factory-style and auto-parts

generic terminals once installed. There's not much difference in length, but the

factory style are much thinner - and most importantly, fit on the board.

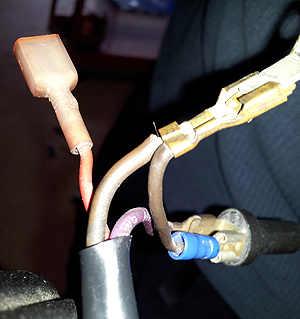

The final task would be to sort out the wiring for the clock and

voltmeter. The eBay harness came with the wires in place, but they too

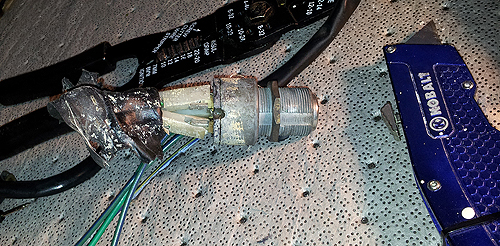

had a serious case of WTF. Here's the wires to the volt meter. Look

closely, because there's a lot of WTF going on.

The only thing right about this? Somebody used brown wire for

the ground. What's wrong?

- That purple wire does not exist in the BMW universe. It

should be grey with a black stripe.

- The red wire should be green with a black stripe.

- The red plastic insulated terminal is crap.

- The purple wire is hot - note that it ends in a

non-insulated crimp-on connector.

- There's a cheap blue insulated crimp-on for one negative

terminal.

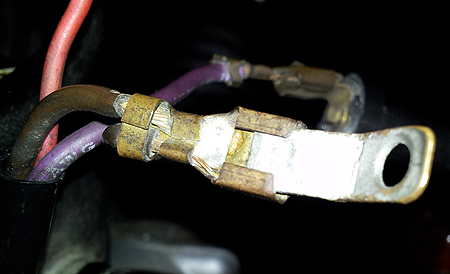

The other negative terminal? That is a work in itself.

|

|

|

That's an industrial-grade connector, but the wrong

type. It should be a male spade. Obviously, someone didn't

have one of those lying around, so they cut off a random bit

of scrap metal, stuck it into a female connector, and

voila! Instant spade terminal! Brilliant! I can see

doing something like this as a temporary fix on the side of

the road. Electrons will flow through it. But as a permanent

solution? What kinda crack were you smoking that day? |

The only solution would be to start from scratch, again using the

proper coloured wires.

Not difficult, but you wonder why the previous owner didn't do this

in the first place.

With everything repaired, I checked and triple-checked all of the

connections to make sure the proper wires were plugged onto the proper

terminals and that nothing was left hanging, and therein lies an

important point:

Since this was my first major wiring overhaul, I probably spent as

much time staring at things as I did doing actual work. I stared

at wires. I stared at wiring diagrams. I compared wires to wiring

diagrams and stared some more. When my eyes glazed over, I took a break

until I was clear-headed enough to return to staring. Because the

potential consequences of getting it wrong were so great - FIRE! - I

really did not want to screw anything up and there was a lot of anxiety.

In the end, though, it was not a difficult project. The basic concept

- match the colors! - is stuff learned in kindergarten. The devil is in

the details: having patience, taking your time, using the right tools

and the right parts.

With everything plugged in, it was time for a test run. Conscious of

the possibility of fire, I rolled the bike outside and connected the

battery. Nothing happened. That was a good sign.

Next, I turned the key.

The headlight came on! I had high and low beam. I had left and right

turn signals, brake lights and idiot lights on the gauge cluster. I felt

the wires inside the headlight and on the harness; nothing was heating

up, so I put on the fuel tank. After sitting a few weeks, it took a few

tries, but the bike finally started and ran like a champ.

In fact, a few things are better than before. The turn signal

indicator on the gauge cluster now works, as does the neutral light,

which was hit-or-miss. There was also some cross-talk in the turn

signals before - a left turn signal would also cause the right bulbs to

glow dimly. Putting a meter on the battery revealed that it is charging

at 14.3 volts at 5,000 RPM, very healthy for an airhead. I also know

that all of the connections are correct - there are no half-assed fixes,

festively coloured wires or mystery lumps hidden inside layers of tape.

The whole project took about 16 hours of actual working time,

including staring. Some of that also involved redoing things, like

replacing the auto-store connectors I initially fitted. I probably spent

$250 on parts and another $75 on tools, all of which is a lot less than

a new harness (which you can't buy), never mind shop time - if there was

even a shop that would do the job within 100 miles, which there isn't. The experience and

knowledge gained? Priceless.

Return home |