Koni Rebuild

Shockingly easy (for the most part)

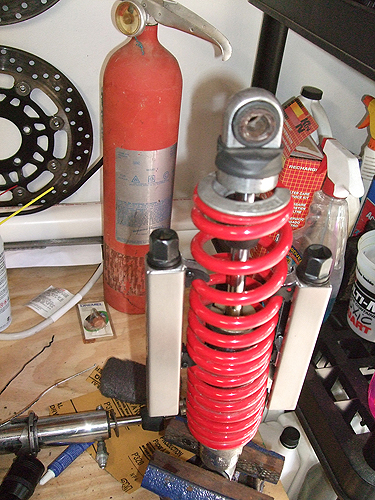

When I bought my BMW a long time ago, it came with a set

of chrome Koni shocks with red powder-coated springs. Like Lester

wheels, Konis were one of those go-to aftermarket modifications

seemingly everyone made. But after 30 years, mine were getting tired.

One of them let me know by puking oil all over itself, as seen in the

picture below. That shot on the left? There's a chrome damper under all

that black dirt.

I decided to get a new set of shocks after running into

a great deal at a vendor at the BMW RA Rally at Barber Motorsports Park.

The new shocks had lighter springs (these Konis have very, very heavy

springs and I figured I could sell the Konis to help defray the cost). A

friend of mine who recently bought an airhead BMW was interested. He does more two-up

riding and touring, so the heavy springs were more suited to him. I

rebuilt them for him as described here. He got a set of rebuilt Konis

for less than half the price of new, and I got to learn how to rebuild

old shocks. Fair deal.

While Koni no longer makes motorcycle shocks, a new

company, cheekily named IKON Suspension, does. In fact, they make pretty

much the same model lineup as the old Koni, and while they're based in Australia, they

have a U.S. Distributor run by a very helpful and patient man, Dave

Gardiner, who will sell you the parts you need to keep your Konis on the

road. You can check out his web site at:

Ikon Suspension USA.

He was also a great resource during the process, answering questions

quickly via email or on the phone. That's refreshing these days.

Dave will sell you a seal kit as well as any other parts

you may need, and he carries parts for a variety of shocks. My

particular shocks were Koni model 7610-1298, "Special D." Some very old

Konis no longer have parts available,

as this rider found out, so check with Dave first. The rubber bumpers on mine were pretty worn out, and I

also needed a bushing so I ordered those in addition to the seal kit. The whole bill was about $60

for the parts and everything came with instructions. He will also rent

the spring compressor and pin spanner you'll need for the job but since

I'm a tool whore I just bought some.

The first step is to remove the spring by compressing it

so that you can remove the retaining ring at the top. There are a number

of different types of spring compressors. I used a set from

Rocky Mountain ATV. It's basically a set of clamps. Set the shock in

a vise, mount one clamp on either side of the spring and begin

tightening them.

It's important to tighten each side just a little at a

time - one turn or two - and to do so evenly to keep the compressors

from slipping. Wear gloves and safety glasses. You will be storing a lot

of energy in that spring and in this case when the instructions warn

that "serious injury may occur," they really mean it. Go slowly. Be patient.

Eventually you will get the spring compressed enough so

that the retaining ring is below the top shock mount so that you can

remove it.

Here's the ring.

But you're not done yet. Loosen the compressors, again

working one or two turns at a time, alternating sides. Take your time!

Continue until the spring is loose enough to remove the compressors.

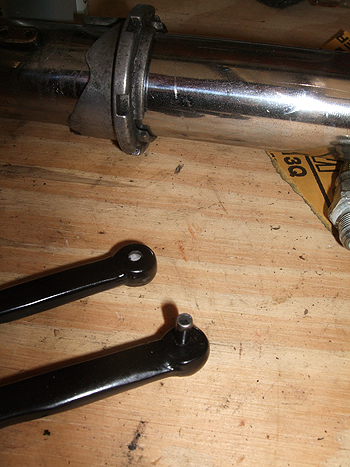

Then slide the spring off. Here are the two damping

units after removing the springs.

Now it's time to work on one shock at a time. That way

you don't get parts mixed up, and if you can't remember how something

goes, you have a reference.

The next step is possibly the most difficult - removing

the gland nut from the cylinder. Begin by putting the bottom eye in the

vice to hold the shock firmly. Now, picture a nut that's been in the

same place for 30 years, subject to rain and dirt. Furthermore, imagine

that this nut has to be grabbed not on the sides by a normal wrench, but

by a spanner that uses two pins to engage two holes in the top. That's

what you're working on.

Here's the nut, partially removed.

Getting to that point wasn't easy. In fact, this part of

the job is legendary. The interwebs are full of stories about stubborn

gland nuts and the various methods of removing them, including violent

assault with hammer and punch, as well as using a torch. I soaked mine

in penetrating oil. For a week. Yes, a solid week.

Even so, my first attempt at removing that nut resulted

in a broken pin on the wrench.

Part of the problem, I think, is that the pins on my

admittedly cheap spanner were too long and therefore prone to flexing

and ultimately breaking. I

ended up buying a better spanner from

Race Tech

suspension. They're heavier and a little longer, so you get more

leverage, and they have many pin sizes (the Konis require 5mm) and the

pins are stubbier.

However, even these wouldn't work at first. The ends of

the spanner are too wide, and the holes in the gland nut are too close

to the damping rod. The side of the arms hit the rod before the pins

could engage. My solution was to grind down the inside portion of the

arms; it didn't take much.

And the wrench finally fit.

Here's the gland nut unscrewed completely.

Now, reach inside with a pick and remove the large o-ring.

Keeping the shock upright, take the whole thing outside and remove the

piston rod and inner cylinder, over a drain pan. This will be messy. On one of mine, the

inner cylinder came out with the rod. On the other, it stayed in the

cylinder at first. In both cases, there is also a large washer that sits

in the bottom of the outer cylinder. It may or may not fall out, but

remove it as well - that's it on the rim of the drain pan.

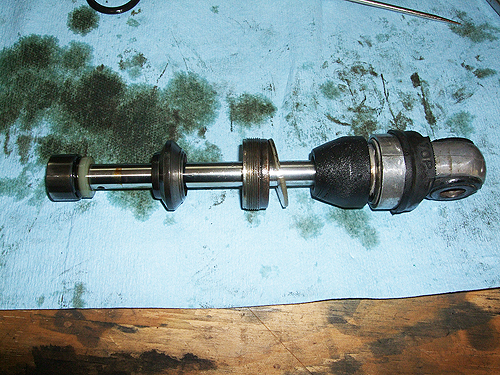

Clean everything off as much as you can. Here's the damper assembly,

including the inner cylinder, laid out on the bench.

And the damper rod itself. Notice the bits on the left side. Those will

come off next.

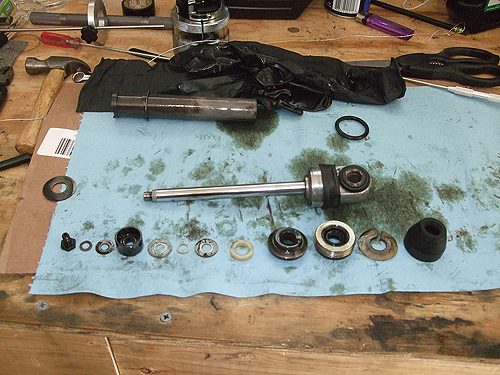

To remove them, mount the top eye in the vice. At the end of the rod,

there is a 12mm bolt.

Remove it with a socket wrench, being careful not to lose any of the

parts that it holds on the end of the damper rod.

Remove the washers, spacers, and assorted bits and lay them out in the

order they came off.

Clean all of the pieces thoroughly, including the inner and outer

cylinders. There will be a lot of sludge built up in there. I like using

brake part cleaner as it cuts through oil and dries quickly. I also took

some chrome polish to the cylinders. If I was really OCD, I could have

polished the retaining ring and other bits, but this isn't a restoration

and I like the patina. The important thing is to make sure there's no

more sludge or dirt to interfere with the fluid damping.

For the rest of the reassembly, from the instructions provided: "Leave the top mount & rod assembled, but check it for wobble - it should be secure. There's a small O-ring for the inner rod/outer rod in the seal kit, located in that top mount - if it's not leaking oil, this is more trouble than it's worth to go into the top mount, just leave it."

Mine did not wobble or leak, so I left it assembled.

Next, remove the seal from the gland nut. One of mine came to pieces in

the process.

Here's the gland nut, the remains of the old seal, and the new one.

And here's the other gland nut and seal. This is the one that was

leaking. Messy.

Clean inside the gland nut, press the new seal in, and get ready to

reassemble in the order that things were removed.

First, put on the rubber bumper and the plastic washer.

Before sliding the gland nut on, lubricate the inside with dielectric

grease. I also wrapped the end of the rod with electrical tape to

prevent the sharp edge from cutting the rubber seal.

After the gland nut, put on the new o-ring and the "flying saucer"

bushing (oriented correctly!). Then place the remaining parts on the end

of the rod, and attach with the 12mm bolt. Dave recommends putting a

spot of loctite - just a dab - on the bolt.

Mount the cylinder in the vice again, by the bottom eye. Put in the

washer and the inner cylinder, and fill the inner cylinder with 80cc of

oil.

Dave recommends 5w, or 7.5 for older bikes. I used 10w at the request of

the shocks' new owner, who prefers heavy damping. If necessary, we can

change it.

As for the rest, according to the instructions:

"Take up the rod/piston/top mount assy and apply a sealant to the threads of the gland nut, to prevent seepage. I use Gascacinch. Don't use a thread locker, you might want to go in there again to change oil, someday.

See that hole in the rod just above the piston? It's going to squirt oil on your shirt when you start pushing the piston into the inner cylinder. Let the "flying saucer" bushing cover it as you put the rod assy in the cylinders and you won't need to change your shirt.

Tighten the gland nut snug. It will turn in to a stopping point on the threads, that's it."

Pump the damping rod a few times to make sure it's working, then

replace the spring by compressing it (carefully!), sliding the

retaining ring on, and decompressing the spring.

Repeat for the other unit and, according to the instructions: "Set shocks on work bench, open beer."

I always follow instructions to the letter.

Here are the before and after shots. The zip ties are there to hold

the bushing in the top mount.

The eagle-eyed will notice that the springs have been

mounted differently on reassembly, with the tighter coils at the bottom.

Keep in mind that they had been powdercoated red by the previous owner,

and after checking photos on the Ikon web site, I put the springs on in

an orientation that matches the photos of the stock, new shocks.

Just in case, I e-mailed Dave to see if one or the other

was correct. His response:

"It doesn't really matter. It just looks better with

the tight coils down."

Return home |