2001 Triumph TT600

Valve Adjustment and Major ServiceAll the usual caveats apply - don't try this at home, RTFM before doing

anything, all service should be performed by a Trained Triumph Service

Technician, take lots of pictures and notes so you know how everything goes back

together, etc.

That said, it's a fiddly though not impossible job. The main thing is to take

your time and be thorough. Double-check and triple-check everything.

First, a little backstory: I bought my TT600 years ago as my

first track bike, and it's served me well.

I paid $2K, and for four years, I never did anything more to the engine than

change the oil and it ran like a top. Then I

started riding my racing SV more. Then I crashed the SV and broke my thumb.

Meanwhile, the TT sat, neglected but not complaining. Finally, with

a fresh battery but the old gas, I tried to fire her up. It took a while, but

she finally started and ran great once warm. Every time I tried to start it

after, though, she didn't wanna. And when she finally did start, she had a hinky

idle and some throttle weirdness until thoroughly warm. So I decided that it was

time for a thorough service: air filter, plugs, fluids and the dreaded Valve

Adjustment. I've done locknut adjusters on my airhead BMW and

Gill's 250

Ninja. I've done sliding rocker arms and shims on a big Kawasaki ZRX 1200 (click

here to see that job). But this required taking out the cams. It scared me.

But it had to be done, so...

I got it on the stand and on the carpet. Fortunately, my garage is

air-conditioned, which makes a huge difference in my comfort level, and

therefore my patience level, which is very important for this sorta thing. The

right side of the tank is dented - was that way when I bought it. Found a decent

used tank on e-bay for $90, so that got replaced too.

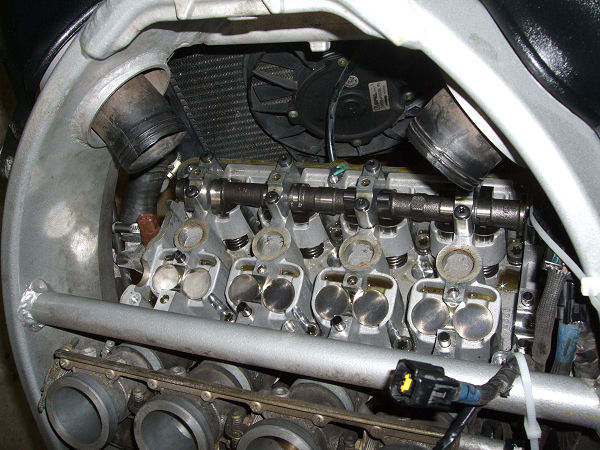

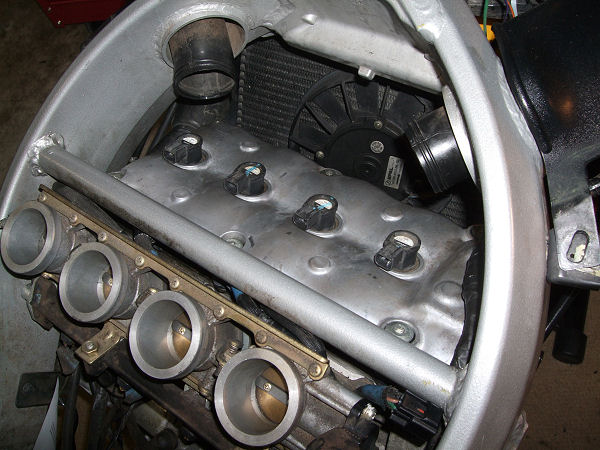

Fairings, tank, airbox and seat off.

Revealing throttle bodies and a lot of tubing and connectors.

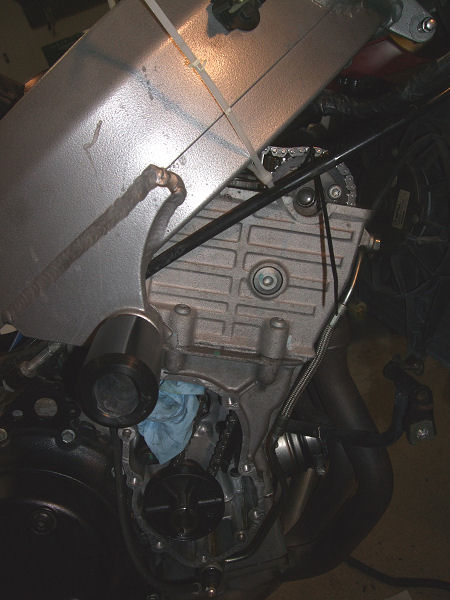

The radiator had to be moved, but not re-moved, to get the valve cover out.

Obviously, we have a li'l leak at the gasket. I suspended the radiator with some

zip-tie to keep stress off the hoses. It's a tight fit, but the cover will come

off through the right side.

Before I even got to the valves, I found a new mess.

That's one of the tubes from the Idle Air Control stepper motor to the throttle

bodies. There are four of 'em. And every damn one was cracked at both ends,

which would explain the starting/idling problem. A new set was ordered, then

backordered. Just in case, I got some vacuum hose from an auto parts store and

improvised, replacing the old rubber.

There's also a similar tube running from the FI back to the ECU. It was

completely knackered. I'm surprised the thing ran at all.

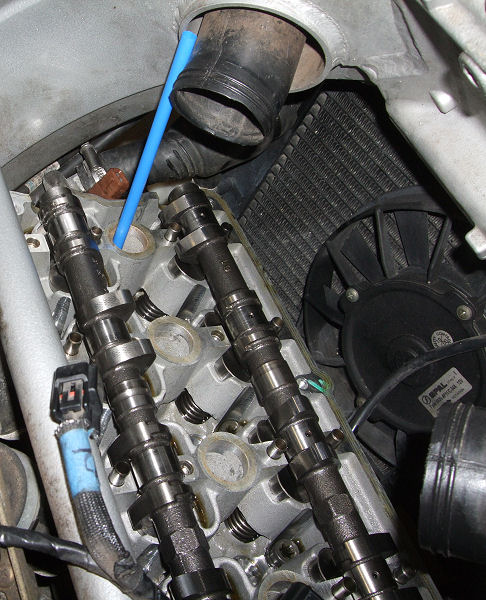

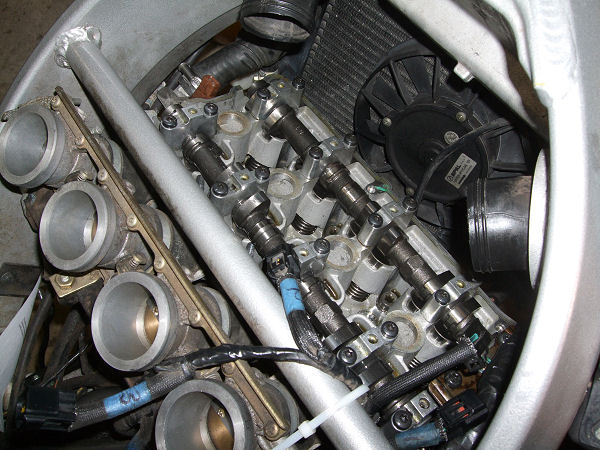

The coils and plugs came out and the valve cover off.

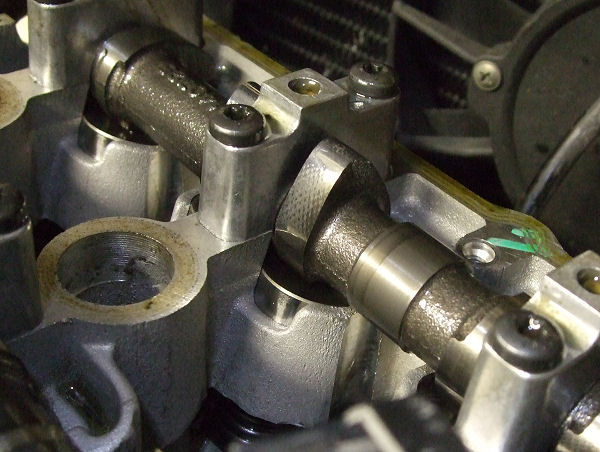

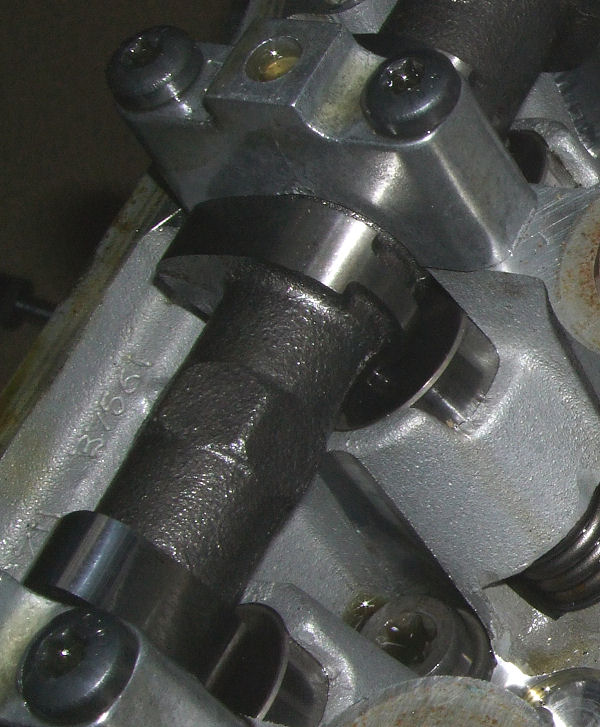

Revealing the guts. This is a cam and bucket. To check clearance, you put it in

second or third gear and rotate the engine with the back tyre until the pointy

end of the cam is pointing away from its respective bucket, then measure with

the feeler gauge. That part's easy.

I was hoping everything would be within acceptable tolerances, but I had four of

16 out of spec (tight). Two on the intake side, two on the exhaust. That meant

the cams had to come out, which sucked. But the rest of the valves were on the

tight side of tolerance anyway, so I figured I'd re-shim everything.

Now, taking the cams out and putting them in ain't that hard. It's a buncha

bolts, and you gotta do 'em in sequence, and a li'l at a time, like a half or

full turn. Easy does it, or things further inside start bumping into each other.

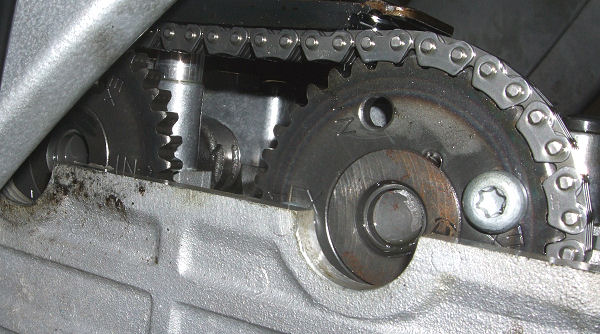

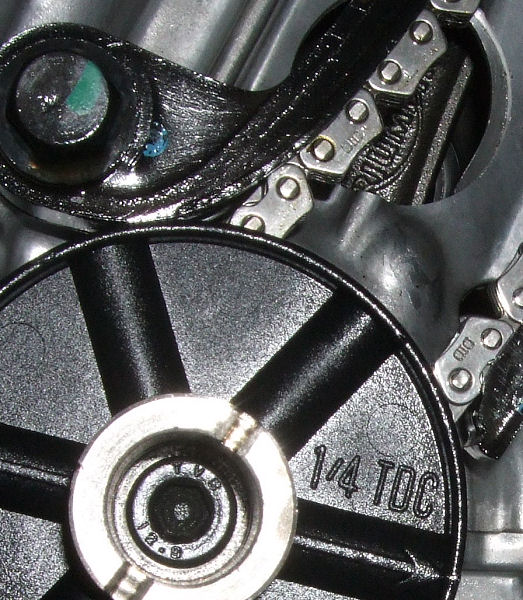

Before that, though, you have to turn the engine so that cylinders 1 and 4 are

at top dead center. Easy enough, since there are handy arrows and markings on

the cam sprockets and the crankshaft. Remove the crankcase breather cover and

turn the crank so that the arrow lines up with the the split between the case

and cylinder, and the markings on the cam sprockets line up with the top of the

head. See the manual for details, but here's how it looks.

First, the cam sprocket marks - lined up nicely.

The crank, however, did not align like the manual says it should. This would be

a source of consternation, but more on that later. The important thing is, I

took pictures of all of this before disassembling anything.

Next, you take out the cam chain tensioner (simple - see the manual) and top

rub/retaining plate, and then you start unscrewing the cam caps. This is fiddly,

since while 1 and 4 are at TDC, the valves on the other cylinders are in various

stages of actuation, so there's pressure on the cam and valves. Patience is

required. Progress is slow and methodical. Once everything's undone, the chain

gets pulled off and the cam comes out. You remove one cam at a time, according

to the Holy Book of Triumph. I removed the intake cam first, then exhaust. The

cams, caps and bolts got laid out in the order they were removed. Here's the

first one

When the cam out, you're facing this. With the bits out, the buckets and shims

are easy to get to.

The buckets come out and the shims replaced one at a time. This is the top of

the valve stem, shim removed.

Beneath each of those buckets is a little tiny shim, 7.48 mm in diameter. They

tend to stay with their bucket when removed, thanks to the oil, but be careful -

you don't want to drop one.

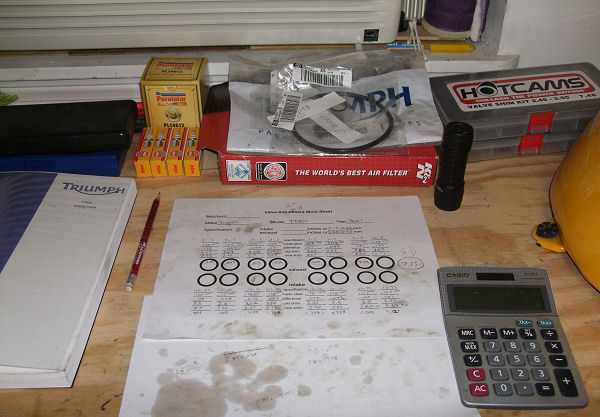

Earlier, all measurements were recorded on a worksheet, along with proper spec

and difference. Did I mention this whole process is very fiddly? As each shim

was removed, it was measured with a micrometer and noted (although the thickness

is printed on them, the printing can wear, as can the shim). Maths were then

performed to determine the correct thickness needed for the replacement shim.

Click here for a worksheet!

Basically take the difference between measured clearance and ideal clearance (I

use the larger, looser end of spec as ideal, as the tendency is to tighten over

time). Then, take size of old shim, subtract the difference from spec (since you

want a larger gap, you're going to use a smaller shim) to get the ideal size of

the new shim.

Simply put:

Old shim size - difference from ideal spec (ideal gap minus measured gap) = new

shim size

or let's say you have an ideal gap of .15mm. Your measured clearance was .11mm.

The difference is .4mm. Your old shim was a 2.6mm.

So 2.6mm - .4mm = 2.2mm for the new shim to achieve the desired gap.

On the worksheet, ideal replacement shim thickness was noted, as was the

anticipated clearance when complete. Since all the math was done beforehand, it

was just a matter of picking out the shim and putting it in, then putting on the

bucket.

And so forth 16 times!

Now, factory shims come in smaller increments, but cost about $8 each, although

some shops will swap shims with you for free. I haven't even been in a shop in

years, so I got an aftermarket shim kit. It has shims in increments of .05mm,

which probably isn't going to give you an exactly matching set of clearances,

but you can get them within 1 or 2 thousandths. Yes, it's a compromise. No,

you're not building a MotoGP motor. Get over it. Or spend $8 a shim.

Now came time for reassembly. Although I had pictures of everything, I was a bit

perplexed as to whether the 1 and 4 pistons were actually at TDC where they were

supposed to be. The Holy Book of Triumph showed pictures of the crank indicator

level and even with the seam between the case and cylinder. But mine clearly was

not. I needed to make sure I was at TDC before putting the cams back in.

In the picture above, you will notice a hole above the crank where you can see the actual rod,

complete with "Triumph" logo embossed. That's one way to check for TDC (1 and 4

rise and fall together), but after consultation with a friend of mine who knows

more about this stuff and who was exceptionally patient and helpful with my many

questions, I went with the low-tech method of stickin' a straw down the No. 1

hole moving the engine back and forth to find the highest point.

I used one from a Circle K Polar Pop - at 75 cents for a

New-York-City-taxable-sized jug o' soda, they're the best deal going. And they

come with reeeely long straws. And unlike screwdrivers, straws won't scratch the

piston.

Problem now was, TDC appeared to be somewhere between even with the crankcase

split, or just past it, as originally noted. Then things got weird.

I slathered everything with a 50/50 mix of moly lube and engine oil, according

to the manual, put the cams in place and put the timing chain on, but when the

crankshaft mark was aligned with the split at the case - as per the manual -

with the chain pulled tight the marks on the cam were off regardless of what

tooth the chain was on.

However, when the marks on the cams were right, the crank was... just past the

crankcase split, where it was before I disassembled the thing. Since that's how

it came, that's how I decided to reassemble it.

I found it easiest to put the exhaust cam in first, then the intake. However,

the chain would slip and do stupid things while I tried to put the intake cam

in, so I attached it to the exhaust cam with a zip tie to keep things from

shifting off the proper tooth. Worked a treat. The white zip tie is running over

the frame and under the cam chain, loosely, to keep it from falling down into

the case while the cams are out or being moved around.

With both cams in place and the chain loosely draped over the sprockets, it was

time to torque down the cams, progressively tightening each of the 10 bolts on

the caps in the order prescribed by the Holy Book of Triumph. What the scripture

doesn't tell you, though, is that the cams will turn slightly as you tighten

them, on accounta the cam lobes contacting the valve buckets.

Fortunately, each cam comes with a cast-in hex nut gizmo - see the pic below - so you can make a fine

adjustment with a wrench once the caps are bolted down (and _before_ you tighten

the chain!).

With everything bolted down and aligned, it was just a matter of fitting the

chain and tensioner and the top plate and making sure the thing would turn

through a couple of rotations without anything stupid happening, like valves

bumping into pistons. A couple of rotations, back to TDC, and the marks lined

up.

Fortunately, nothing stupid happened. But when I checked the clearances again, I

found one valve way tight. That meant taking the whole mess apart and doing it

over again, which sucked. Turns out, I'd misread the shim size and used a 2.6mm

instead of 2.5, which made me feel like an idiot for not double-checking the

printed size with a micrometer and then triple checking after that. But since

I'd already done the assembly and disassembly once, I managed to get the cam

out, put in the right shim and get it all back together in about 45 minutes,

which included cigarette breaks and time allotted to kick myself for being

sloppy.

Clearances were re-measured, everything was on the loose end of spec, and the

engine spun without stupid things happening. Time for...

Then we gotta put the covers back on. The Holy Book of Triumph just says to put the gasket

on the cover, place the cover on the head with some silicone in the specified

spots, and tighten. But it ain't that simple. The gasket is a floppy one-piece

mess that includes seals for the spark plug holes in a string down the middle.

And no, you can't set it on the engine and then put the cover on, because there

is a slotted groove along the top that fits in the valve cover and it's easier

to do it this way. Trust me. I tried both.

I've worked on other bikes with separate circular gaskets for each plug, and it

was easy. This is one of those things that convinces me that engineers and

designers are people who never actually have to WORK on the things they create.

Keeping that line of plug gaskets in place while fitting the cover in the tight

space between the frame and engine was a pain innee ass.

Cover on, plugs and coils in.

Next order of business was to fix the vacuum leaks. Every line from the stepper

motor got replaced, which delayed the whole project. The parts ended up

backordered. Could be worse. Could be an Aprilia.

After that, the airbox went back on, with a new filter.

I also put on the new tank. I used the hardware from the old tank, including the

fuel pump assembly. That was a revelation! I forgot to take a proper "before"

picture of the accumulation of crud that had built up, but here it is

mid-cleaning. Modern gas is crap.

Then the tank went on.

And the rest was put back together. As sportbikes go, it's a bit roundish and

old-school, but I think it still looks sharp.

I had the time for a test ride, but opted instead to just try starting it and

running it for a few minutes. After all, I was planning to take it for a long

run the next day. It took a bit of cranking on acounta the entire fuel system

being dry, but when it fired up, it ran like the proverbial top. I let it cool

off, and on the next attempt it started like a champ.

False confidence!

I took it out the next morning and, while it ran and revved smoothly, once fully

up to temperature, it would stall if I closed the throttle completely. My

dumbass mistake. After adjusting the valves and fixing the vacuum lines, of

course the idle was likely to change.

It's always the little things.

Things I learned along the way:

- Get the manual! It will save you endless grief and guessing.

- You can do it. It just takes patience.

- Triple-check everything.

- Plug up any holes - spark plug, crank case, etc. - in case you drop

something.

- You will drop something. A magnet-on-a-stick tool is a must-have

- I take the most-used feeler gauge blades out of the tool and tie 'em on

a long loop of string. Makes them easier to access, and if you drop a blade,

you can retrieve it easily.

- Do not confuse inches and mm! My feeler gauge is in inches. Conversion

is Inch X 25.4 = mm and mm X 0.0393701 = inches. I have the formulas tacked

up on my wall.

- Use torque wrenches! I had to buy one because the torque on the cam caps

is only 10nm, which is not much, and I didn't have one that would go that

low. It's an excuse to buy a new tool.

- Recheck clearances after refitting the cams.

- Do a thorough warm-up and test ride and idle speed check!

Return home

|