|

The Half of Knowledge The Half of Knowledge

Solving Throttle woes on a 2006 Sprint 1050ST

The Fourth Thesis of the Zimmerframe Manifesto is "Except for cases of epic

mechanical catastrophe, you're probably better off buying tools and shop

manuals with the money you'd spend on labor."

This is not said to cast

aspersions on professional mechanics - the good ones, who know what they're

doing and do the job well, are worth their weight in fine British ale.

Unfortunately, my experience has been less than stellar, and after a rapid

succession of "professional" screw-ups, including the

near-catastrophic failure to tighten an

engine mounting bolt, I finally decided I was perfectly capable of making

such

bonehead mistakes myself, rather than paying someone else $90-$120 per hour to make

them. So far it has worked out well. I've kept the bikes in shape, saved

money, learned a lot and

built up a decent collection of tools.

But a recent issue had me considering

abandoning all hope and visiting a dealer.

My now-aging Triumph Sprint developed an annoying habit of stalling

when I rolled off the throttle. It ran fine while on the gas, but would not idle properly when warm.

Sometimes it idled too slowly, then gradually built revs. Sometimes it just died.

If I held the throttle open, I could keep the engine going at stoplights. More annoyingly, the problem was intermittent,

with the thing behaving in a civilised manner one day, and acting up the

next.

But what was wrong?

This question highlights the biggest difference I've found between the

professional mechanic and mortals like me: the ability to swiftly diagnose a problem.

Fixing things is usually pretty straightforward. But knowing what to fix,

that can be an art form.

Some of the true professional's diagnostic acumen is based on experience.

Old-timers

have likely seen the problem before, so they know what to do.

Modern electronics have made the job somewhat easier, with computer

interfaces spitting out "OBD" codes that you can then

look up in the Holy Book of Faults to find the problem. However, the

equipment to do so is prohibitively expensive. Triumph's diagnostic gizmo

was $12,0000 last I checked, and only available to dealers. Ducati has a

system that costs 10 times as much and sends the codes directly to the

Mothership hovering over Bologna.

For the rest of us, there's Google, web forums, Clymer and Haynes, none

of which were helpful in this case. As the sign over Dodd Hall at my alma

mater says, "The half of knowledge is to know where to find knowledge," but

despite my best efforts, knowledge in this case was hard to come by.

Part of the problem lies in the voodoo that makes modern, digital fuel

injection systems work.

The basic issue was simple: The throttles were not open enough at idle.

While carburetors operate on arcane principles of classical witchcraft, they are

at least physical entities - tangible, analog devices designed to harness

the elements of air, liquid and fire. Turn certain screws the right way, set

needles in a certain slot, bend float adjustment tabs just so, sacrifice a

goat or two in the name of Beelzebub and you're off. And on most carbureted

bikes, you can turn a single idle speed screw and, all else being right and

your goats of sufficient quality to please the Horned Master, the problem is

solved.

Fuel injection, while simpler from an end-user point of view because

there is no "choke" or other apparatus that needs to be messed with to get

the engine started, is an

entirely different level of complexity, involving a variety of sensors,

computer programs, motors and assemblies that must all communicate

harmoniously via

"electrons" sending messages to and from each, telling them what they are

doing and what everything else should be doing in response, all while

remaining invisible to the human eye. It is voodoo.

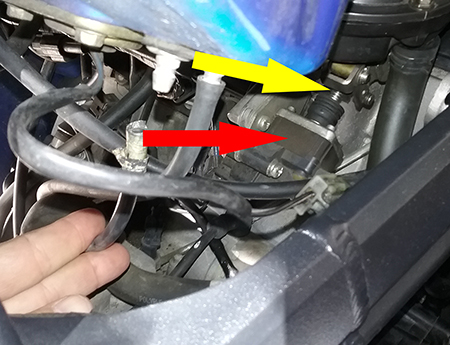

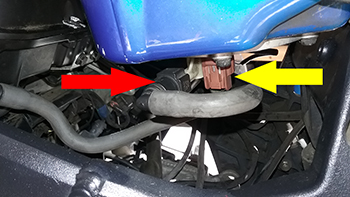

The Idle Stepper Control unit (red arrow)

regulates idle speed by opening the throttle with its infernal

proboscis (yellow arrow)

according to instructions from the voodoo gods. |

On the Sprint, idle speed is not mechanically adjustable. Instead, the

throttle cables are actually set so they are slack at idle, and

an Idle Stepper Control (ISC) motor regulates the opening of the throttle

bodies at idle. The ISC gets its marching orders from the voodoo god, otherwise known as the Electronic Control Unit (ECU). To make its

decision, the ECU gets information from a variety of sensors, including

Engine Speed, Manifold Absolute Pressure, Throttle Position and more. A problem

with any one sensor, or the ISC motor, or the ECU, can cause havoc

everywhere else, which is also why I am confident that we will never be

subjugated by sentient robot overlords - their sensors will malfunction.

My initial inquiries into the Delphic Oracle otherwise known as the

Triumph RAT

forum left me clueless. Yes, others have had similar problems, but the

cause was different in each case. The first step, of course, is to make sure

everything is properly adjusted. Sure, some adjustments are available, but

in addition to hand tools, they require a computer. Because voodoo.

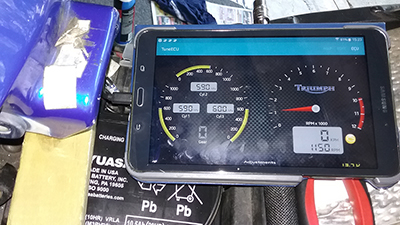

Above, diagnostics with TuneECU. Below, cylinder

pressures

during throttle body sync, getting closer to having all numbers

the same. The readings are in hectopascals, a Pascal being a unit of measurement for internal

pressure (among other things), and a "hecto" being 100 of them. It's named after Blaise Pascal, a

French scientist who probably wonders why no one calls their kid

Blaise any more.

|

Fortunately, you do not have to shell out $12,000 and open a Triumph

dealership do perform basic diagnostics and adjustment on older Triumphs

(NOTE: newer ones have anti-tamper software, so if your bike is newer than

2015, you're SOL and at the mercy of the dealer). A very generous programmer has developed

TuneECU, free for

Windows and cheap for Android users, that lets you do many of the things the

dealer can. I loaded it onto my Android tablet, ordered the appropriate

Lonelec cable, plugged it into the ECU interface and... got nothing

significant.

No fault codes were present, although the throttle bodies were out of

sync, meaning they were opening at slightly different rates, so each

cylinder was getting slightly different amounts of air and fuel, which can

potentially confuse the voodoo gods. Since that's a possible cause of poor idling, I fixed

that. I won't bother telling you how, since

THIS GUY does a much

better job, with video. Basically I did what he did, then went for a

ride. And stalled a few times.

Clearly, throttle sync was not the problem.

That left a problem with either the sensors or the ISC motor (the most likely

suspect, and $200 to replace) all of which would have to be changed one at a

time until the offending unit was found. Since the parts start at $100 each,

new, it could be a pricey proposition, since nothing showed up as faulty on

the computer.

I did notice, while using the TuneECU, that the Throttle Position Sensor

(TPS) was slightly off. It should send .60 volts at rest, + or - .02. Mine

was reading .65, so it was off, and possibly the source of the problem.

Why didn't I fix it when I first noticed the discrepancy, you ask?

Because adjusting the TPS, - a simple job involving loosening two

screws and turning the unit until the voltage is correct - requires

dismantling much of the bike, that's why.

Above: Location of the Throttle Position

Sensor, too close to the frame to allow use of a security torx

tool (bottom) without completely removing the throttle body |

Throttle position Sensor |

|

Those two screws are special "security torx" screws. They are jammed in next to the frame, and the only way to get

to them is to remove the entire throttle body assembly, which requires

removing the airbox, which requires removing the tank, which requires

removing the seat, which requires removing bodywork, which requires removing

the mounts for the panniers, not to mention about 15 electrical and vacuum

connections. Because, once again - the people who design motorcycles

obviously do not work on motorcycles.

This posed an additional dilemma, because in my miserly search for used parts that

might be needed, I found an entire throttle body assembly from a

same-year Sprint, with 12,000 miles, in what looked to be excellent shape,

for $80 on eBay. The part included the TPS and the stepper motor - an entire

package that Triumph sells for $2,250 new. I hit "Buy It Now" and the part

was at my door a few days later.

Now I was faced with a choice: I could dismantle the bike, adjust the TPS

on the old throttle body and hope that would cure the problem. Or, since I

had a new/used assembly that included the stepper motor, I could put that on

instead. Both required the same amount of labor, although if the TPS

adjustment on the old assembly was not the problem, I'd have to take the

bike apart all

over again to put the new/used throttle body assembly on.

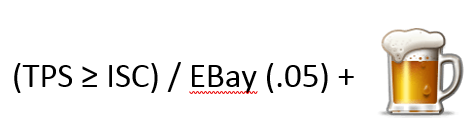

Given that the TPS was off by only 3 hundredths of a volt, and that the

problem was intermittent, and that sometimes, while sitting at a light,

the idle would creep up from 800 to its proper 1250, I suspected the

problem was not the TPS, but the stepper motor or something else, and

that hours of labour would be for naught and just I'd end up putting the

new one on anyway. Thus it became an exercise in simple calculation:

It was a matter of weighing the probability of the TPS adjustment

being the problem (low) against the possibility that it was something

else (high) and dividing by the potential that the used eBay part was

defective (five percent, or .05). Once all those maths were complete, I

added Beer, because that is the last step an any amateur engineering

equation, and hit upon the solution - I'd replace the whole mess.

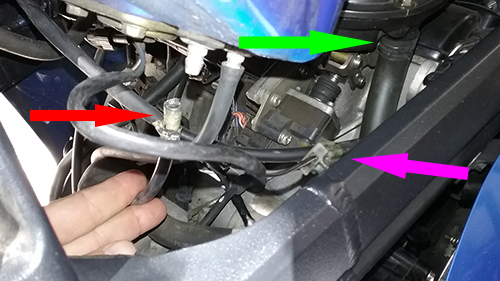

Gas tank removal requires disconnecting the fuel feeder line (red arrow) and electrical connection to the fuel pump. There are also two

vent hoses and an electrical connection for the fuel gauge on the other side.

Handy tip: An old tyre makes a great tank stand - keeps it from

being scratched, and keeps the parts sticking out underneath

from getting bent.

|

With the decision made, it was time to disassemble the top of the

bike and swap parts. As noted before, a lot of stuff has to be removed,

starting with the seat, pannier frame and seat cowl. Why? Because all of

that is in the way of the ONE bolt necessary to remove the gas tank,

because designers... you know the rest.

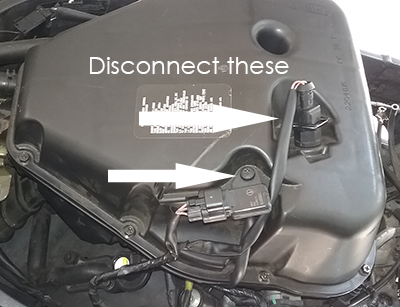

Once the fuel tank is off, remove the airbox by unscrewing the two bolts

at the rear and one at the front, as well as vent hoses and electrical

connections at the top (pictured). You do NOT need to remove the 74 or so

bolts holding the thing together unless you're replacing the air filter. You

will also have to disconnect a bunch of hoses and electrical plugs. As always, take lots of pictures so

you can remember where everything goes. Because you will NOT remember where

everything goes.

Just a few of the hoses and electrical

connections that must be removed to get the tank off and get to

the throttle bodies. Red: vent tube. Green: crankcase vent to

airbox.

Purple: Fuel level sensor connection |

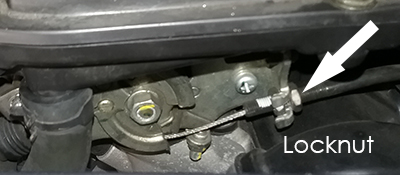

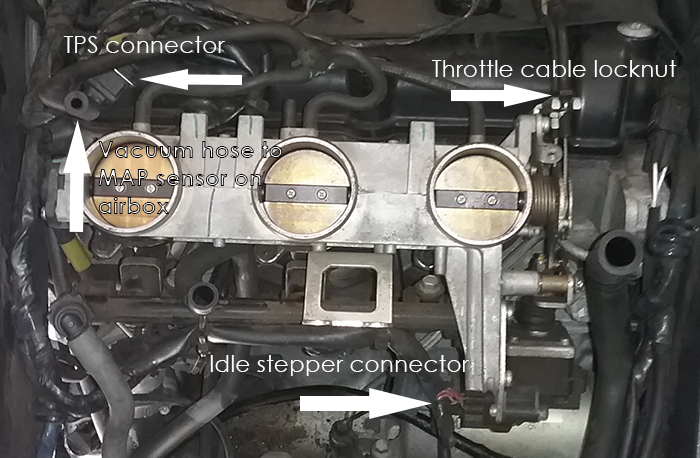

Once all of that is done, you will find yourself staring into the

belly of the beast - the throttle body assembly and its associated

gizmos and widgets. Begin by disconnecting the throttle cables. This

requires loosening a locknut and manipulating the cable out of its slot.

CAUTION: Make a note, or make a mark, and take pictures showing where

the nuts were located along the length of the threaded portion of the

throttle cable sleeve ends. This will put you in the general vicinity

when it comes time to adjust them on reassembly.

|

Lower throttle cable, showing locknut

and paint to mark position |

Items that need to be disconnected include:

Finally, loosen the clamps holding the throttle body assembly to the

manifold. Joke's on you! They're a pain to get to, and allen-head screws to

boot. Be patient and don't drop anything. The clamps just need to be

loosened, not unscrewed entirely. Here's one of them, hiding under the

assembly.

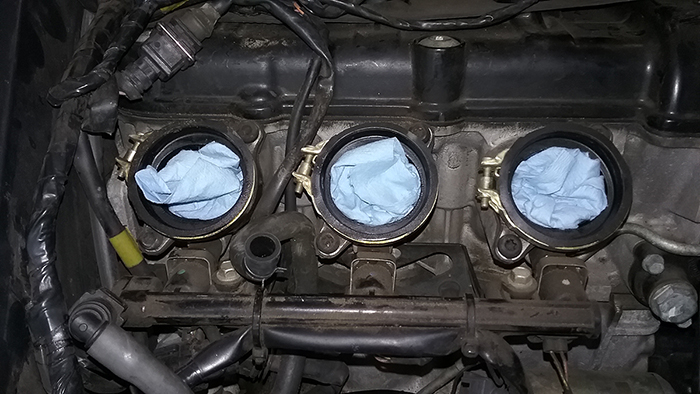

Here's the assembly just coming off. You're looking at the left side.

That's the throttle position sensor marked with the blue paint from the

factory adjustment. Everything will need to be cleaned before

reassembling.

But before cleaning, stuff the intakes with shop rags to keep crap

from falling down into the motor. Note that the throttle bodies only

regulate airflow. Fuel is delivered by injectors, fed by the fuel rail -

that's the tube along the bottom.

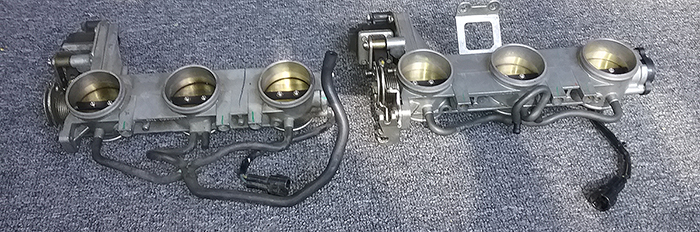

And the throttle bodies side by side. The old one is on the left. I

transferred the bracket from the old one to the semi-new one because new one

was bent. That's where the rear of the airbox attaches. Remember, this whole

thing, with throttle position sensor and stepper motor, will cost more than

$2000 from Triumph. Ebay is awesome.

Before everything goes back together, plug in the throttle position

sensor and adjust it according to the instructions, using the TuneECU

software,

as described in this handy guide. Then, as they say in the manuals:

assembly is the reverse of disassembly. Pop the adjusted throttle body

on, tighten the clamps, plug everything in and keep going from bottom to

top. It's pretty straightforward because you took lots of pictures of

everything as you took it apart, right? Once everything's together, you

can do a "reset adaptation," which basically means running bike for

about 10 minutes from dead cold while the voodoo gods "learn" where the

idle should be.

Once everything was together and all adjustments and adaptations were

done, it was time for a test ride. Much to my delight, the bike no

longer died when I rolled off the throttle. It idled properly. Happy

days! Until I rode it to work the next morning.

Rolling through commuter traffic, the Sprint started sputtering and

surging. If I rolled the throttle off, it idled fine. If I rolled it on,

it revved like a champ and didn't miss a beat. The misbehaviour was only

present at very small throttle openings, the kind you're at when wending

your way through traffic at 30 or 40 miles an hour. And it was

excruciating.

So it was back down the rabbit hole of internet disinformation,

searching for a clue. All of the usual suspects showed up in my searches

- throttle position sensor, throttle body sync, etc. But all of that was

correct and accounted for. Then a small sentence caught my eye. It noted

that while fueling is controlled primarily by the throttle position

sensor, at very small throttle openings, the ECU uses readings from the

MAP sensor to determine the correct amount of fuel. This was the area

where I was having problems. I was onto something.

Turns out, MAP stands for "Manifold Absolute Pressure," and basically

means "how much air the engine is sucking through the throttle

holes." Or, if

you're technically inclined,

go to this explanation and knock yourself out with the knowledge.

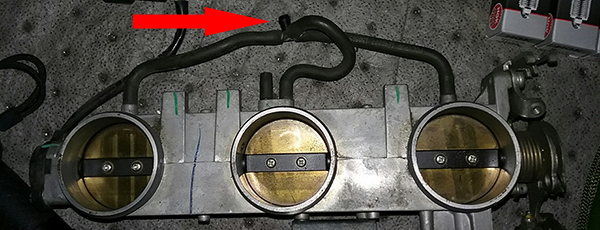

Simply put, each throttle body has a little hole in it, that connects

to a hose, that runs to a connector that joins all three to a single

hose that goes to the MAP sensor. Here are the hoses up to the

connector:

Here is the MAP sensor, mounted on the airbox. The hose from the throttle

body assembly is shown by the white arrow.

Usually, a bad MAP sensor would be indicated by a fault code, and I

had gotten one when I first reassembled the bike, which should have been

a DUH moment. But once cleared, it never returned. Was it bad? There's

no easy way to test it, so again, I applied the same logic used to

determine throttle body replacement substituting MAP sensor for throttle

position sensor and doubling the volume of Beer.

New from Triumph, a map sensor is $100. Used on eBay? Around $10.

I bought two.

Fortunately, replacing the MAP sensor is not as involved, although

pannier mounts, seat, rear cowl and tank have to come off - all to undo

a single screw and pull a hose. For good measure, I took the airbox

again as well and rerouted the hoses from the throttle body. They sit in a tight

space. If they were pinched, they could give an inaccurate reading to

the sensor. It was an extra 20 minutes for peace of mind.

After reassembly, the test ride, and - to my surprise at this point -

everything worked as it should. No more stumbling and surging. It took a

while, but I had finally found some Knowledge (if not all) and fixed the

thing for $120. Time for...

Jameson's Irish, in a Jorvik Viking Center glass

Return home

|