Honey, why does the house smell like Petrol?

Fixing Triumph fuel fittings that should have been

fixed before they left the drawing board

Ready for its closeup

Miss Gill's Speed Four in the studio of a local TV station, where they usually film their cooking segments.

We were there to promote Capital City Bikefest. |

The Triumph Speed Four is a little-known gem of a motorcycle based on the

fully-faired TT600 supersport.

But where the TT600 was released too early - it was the first digitally fuel-injected 600cc bike on the market

and suffered from poor fuel mapping and consequently horrible reviews - the

Speed Four came out after the issues were resolved and continued in the

Triumph lineup even after the Daytona 675 came out.

Triumph made little compromise with the Speed Four. Unlike many factory

streetfighters which substitute dirt-bike bars and other items, it keeps the

clip-on bars and high pegs of the donor bike. While there was some mild

de-tuning (a few less horses, a few more torques) Triumph truly hung a pair

of lights on a TT600 chassis, fashioned some missile-launcher intake tubes

to replace the ram air ducts on the fairing, and called it a day. In a 2008 Ride magazine

reader's poll, the Speed Four - then out of production - still beat the

Daytona 675 for handling and suspension. It was that good.

However, like many Triumphs, including the TT600, the Daytona 955,

Sprint 955 and others, it suffers from a design defect that is

inexcusable: it uses plastic "dry break" quick connectors to plug the

fuel lines to the gas tank.

You don't have to be an engineer to predict what is going to happen to

bits of plastic subjected to vibration and repeated heating and cooling

over time. It's going to harden, and it's going to crack. And when it is

the only thing standing between a tank full of petrol and a hot engine,

you have a very dangerous situation on your hands.

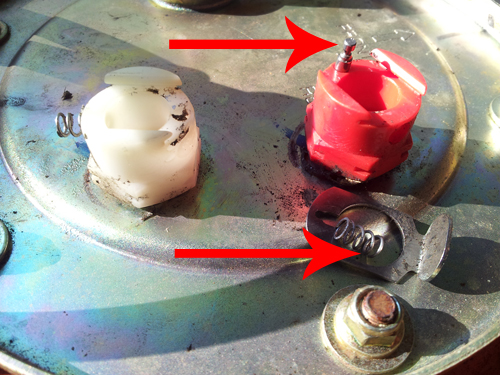

Sure, Derek, those'll hold up to years of heat and vibration

- the recalled fuel couplings. |

Triumph acknowledged half the problem, replacing the plastic male

fittings with metal ones for free as part of a recall. However, they

refused to replace the plastic female fittings under the tank. Sure, if

they failed while under warranty, you got more plastic fittings. If they

failed out of warranty, y'er on y'er own, mate.

Part of this is undoubtedly expense-related. Replacing the hose

couplings takes five minutes. Metal fittings are more expensive, and

replacing the tank fittings takes more like an hour and requires

draining the tank and a uttering lot of profanity, since they were

installed with an epoxy-like sealant that causes them to break off. More

on that in a minute.

The bottom line is that Triumph will not admit the problem. But there

shouldn't have been a problem in the first place. Even the most gormless

stoner sitting in the corner of a rural Kentucky high school shop class could tell you

that it would be better to use metal fittings, but this was designed by

engineers, who probably never took a shop class in their lives. Similar

issues often crop up, which makes me believe that those who design bikes

and cars have probably never held an actual wrench, although they may

have seen CAD drawings of one. That is why, when I am elected Dictator

for Life, no one shall be granted an engineering degree without spending

at least one semester getting their hands dirty in an actual repair

shop.

In the case of Miss Gill's Speed Four, the failure came to light due to

the odor of gas in the garage. This is not unusual, as there are several

bikes with manual fuel petcocks that have to be shut off, and sometimes

someone forgets to shut them off.

However, when the house itself began to smell of gasoline, we knew it

was a bigger issue. A sniff test singled out the bike, and

when the tank was unbolted, gas began dribbling out of the broken fitting.

There's your problem.

If you look closely, you'll see circular scratches on the plate around

the fittings on the right (the one on the left is the electrical

connection for the fuel pump). Apparently this is not the first time the

bike has had this problem. It probably got fixed under warranty. With

more plastic crap.

Step 1 is to drain the tank of fuel, which is a little difficult because

it will only dribble out of the broken connection. It's easier and

faster to open the filler cap and dump it. I have a plastic bin that I

use just for that purpose. Keep it clean and you can reuse the gas, or

put it in your lawn mower or car.

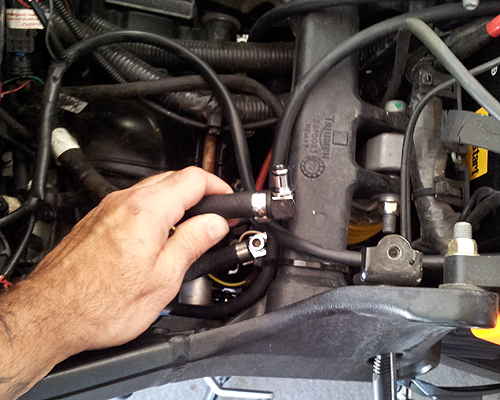

Next, you have to remove the locking hardware on the fittings by pushing down

on the little plunger and removing the sliding plate. There is a spring

on the side of the plate and one under the plunger - do not let them fly

out.

The reason for disassembly is so you can use a deep socket to remove the

fittings, rather than a wrench, reasoning that having six points of

contact will more evenly distribute the torque and make the fitting less

likely to break off.

The joke's on you! The fitting will break off anyway.

Seriously. Unless you are very lucky (and if the fittings do unscrew

without breaking, go buy a lottery ticket immediately!), the fittings

will break off flush with the base and you are now down the rabbit hole.

The next steps I describe may be somewhat controversial, as the

interwebs are already

full of stories by other

unfortunate owners who

have

fixed this very same problem (even though Triumph says there's no

problem). You must remove the threaded parts, but to do that, you must

remove the bits of valve left inside the threaded parts, and some of

those bits could potentially fall into the fuel pump assembly, which

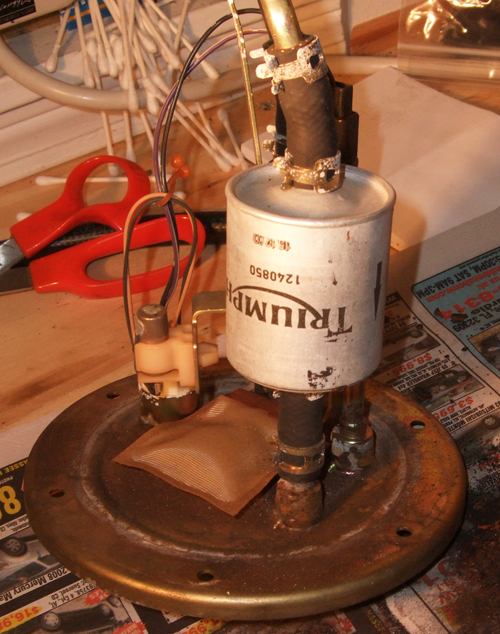

looks like this, from my TT600.

To get there, you must remove the assembly from the tank and disassemble

it, which will inevitably mean ordering new parts, especially the giant

o-ring that seals the whole thing when you reassemble. Unless you have

spare parts lying around, figure at least an extra week. Many owners do

this complete disassembly.

Or you could just start pulling bits out with pliers like I did, being

careful not to drop anything down the hole. I didn't. But it's a small

hole and the parts are fairly large - remember that this is actually a

valve made to stop up the hole when the fuel hose is disconnected, so of

course it is larger than the hole.

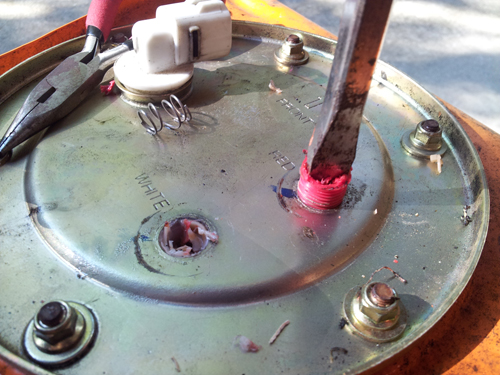

Once you get the valve out, you can use one of two methods to remove the

remaining fitting. I used both. The first involves taking a large

screwdriver and heating it with a torch - preferably away from the tank

and any residual fuel or fumes - then sticking it into the plastic

fitting, where it will melt two slots. Remove the screwdriver and let it

cool, then insert the screwdriver into the slots and carefully turn.

The other method is the tried-and-true ez-out. The fittings requre a

large one, and you'll probably have to buy it separately because most

sets do not include one large enough. I already had one, because I have

a TT600, which had the plastic fuel fittings, and you can guess the

rest. Anyway, gently tap the tool into the fitting until it grabs

sufficiently and then turn.

Once those are out, you are left with a bunch of crappy thread sealant

that needs to be cleaned out.

I used a small awl to scrape the threads clean. Since the bits of gunk

ARE smaller than the hole into the fuel pump assembly, I held a shop vac

over the thing while I scraped so that any dust and chunks were sucked up while I

cleaned, rather than falling down into the pump.

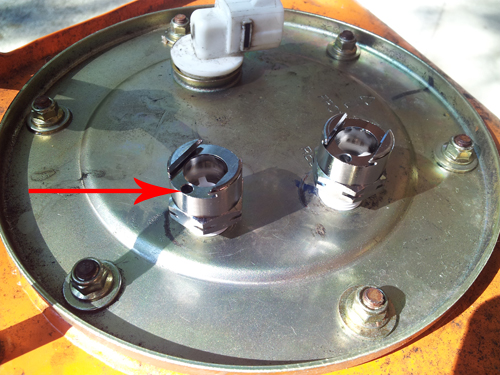

Once cleaned, it's time to insert the new fittings. These are not

standard hardware-store items. The problem with the plastic connectors

was so bad that Team

Triumph in Wisconsin actually went to the trouble of putting

together kits with metal connectors, but those are no longer available. I got mine online from

Quick Couplings.

The tank fittings use 1/4" British Standard Pipe Taper (BSPT).

Here's more than you want to know about that. The hose fittings are

different sizes, because the send and return hoses are different sizes.

You can re-use the hose fittings if they have already been replaced with

metal items, although you may want to put new o-rings on.

Here are the part numbers for everything:

- LC23004 - 1/4 Hose Barb Non-Valved Elbow Coupling Insert

- LC23006 - 3/8 Hose Barb Non-Valved Elbow Coupling Insert

- LCD10004BSPT - 1/4 BSPT Valved Coupling Body (you'll need two of

these)

I used plumbing tape to help seal the threads (some interwebs say yea,

some say nay, use your own judgement). You do not want to screw the new

fittings all the way into the tank; you'll strip the threads. BSPT

threads are designed with a taper (hence the name) that increases toward

the base, sorta like a wine cork with threads. Screw it in tight enough

to seal, no more. You will have to disassemble the locking mechanism if

you want to use a deep socket. The arrow below shows the hole where the

spring and plunger go.

Once tightened, reassemble the locking mechanism and you're finished

with the tank.

If you're putting on new hose fittings, do that. Note how the top hose

(3/8") is larger than the bottom (although both use the same size insert

for the coupling with the tank fitting).

Before reassembly, I used some hi-viz orange duct tape to mark which

hose went to the "red" fitting. Make sure you plug the right hose into

the right fitting.

That's it. Reassemble. Refuel. Ride.

Return home